Thermal Vision,

Electrical Precision

ITC Certified Thermographer/Licensed Electrician with 30 years of experience and 15 years in the Fire Industry

Thermal Vision,

Electrical Precision

ITC Certified Thermographer/Licensed Electrician with 30 years of experience and 15 years in the Fire Industry

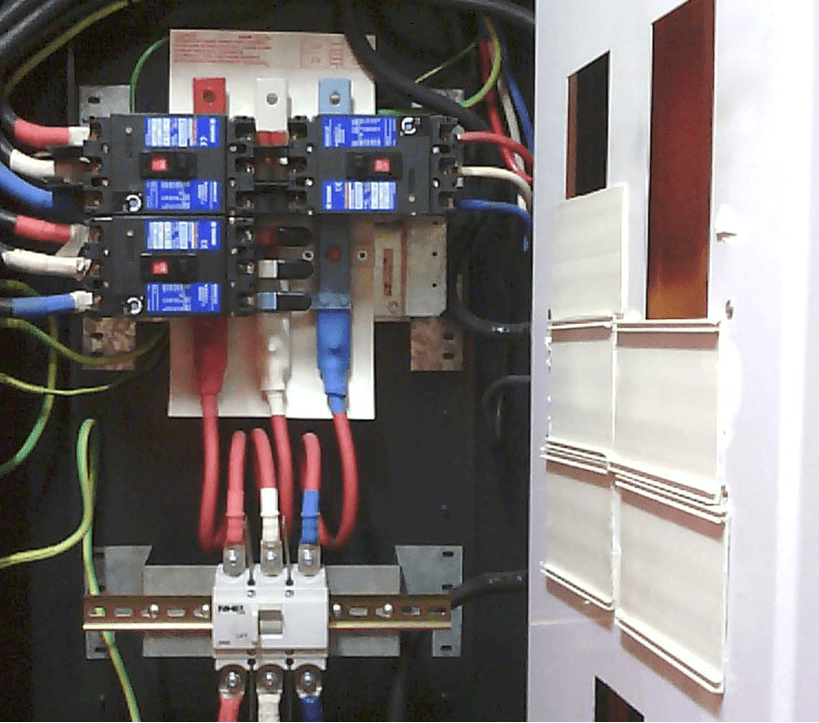

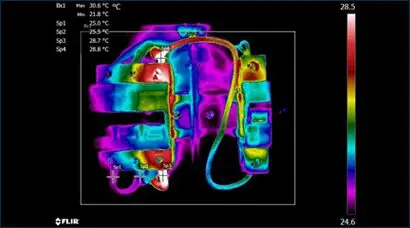

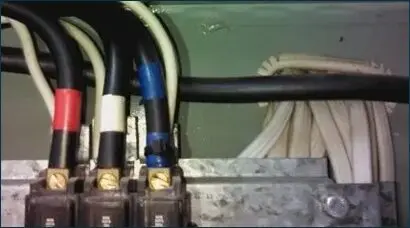

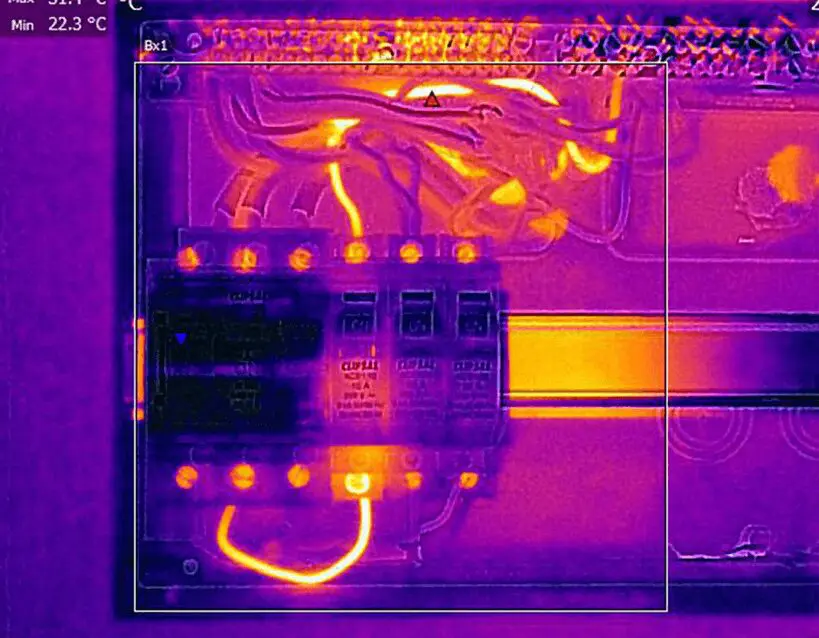

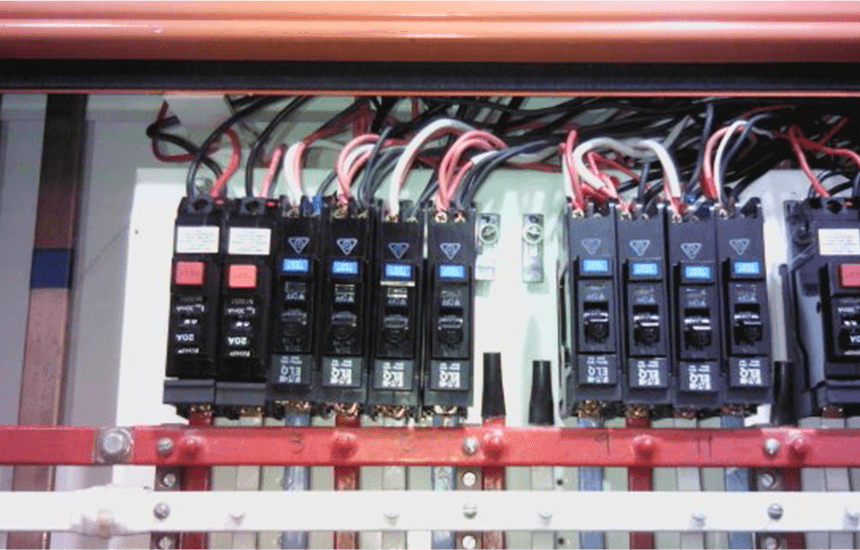

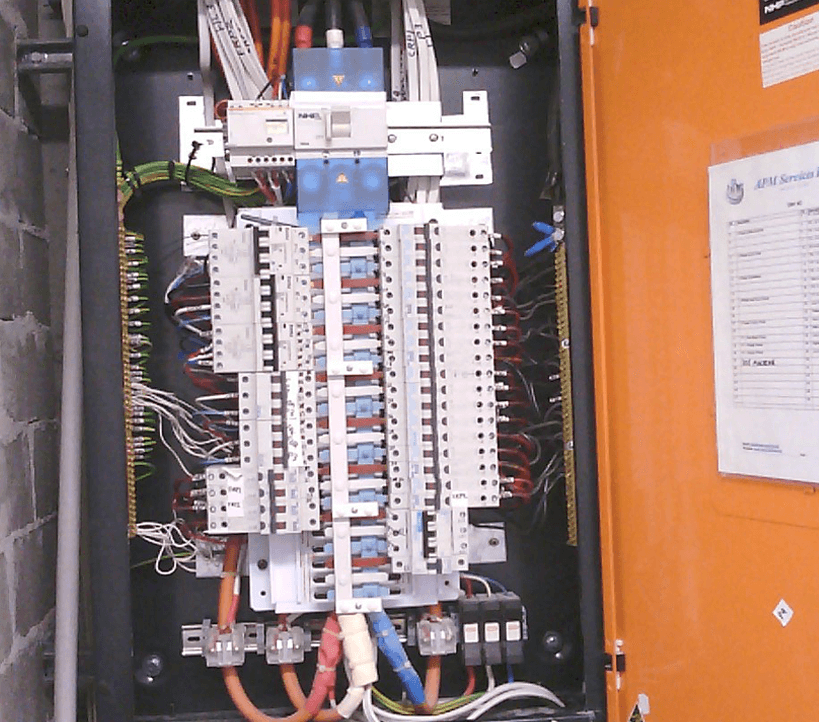

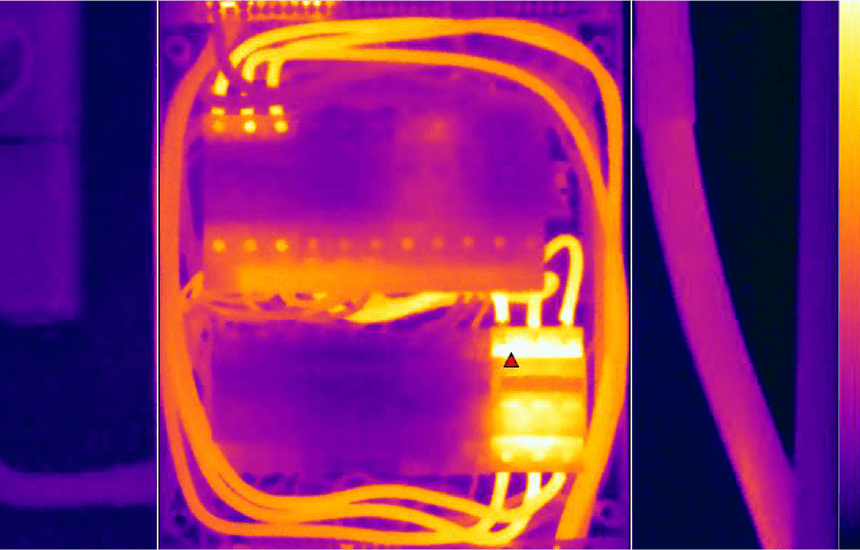

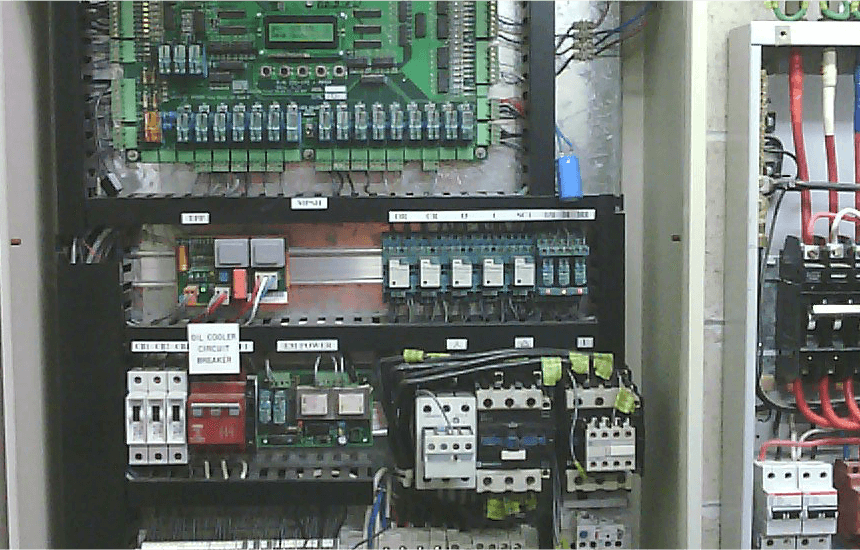

Thermal Scanning Visuals

Professional Electrical Services & Thermography in New South Wales

Maratustech, serving the Sydney, Newcastle, and Central Coast areas, specialises in electrical services, thermography, and fire industry solutions. With 30 years of electrical experience and ITC Certified thermographer, we offer precise thermal scanning of switchboards using top-quality cameras.

What Is Thermal Imaging Scanning?

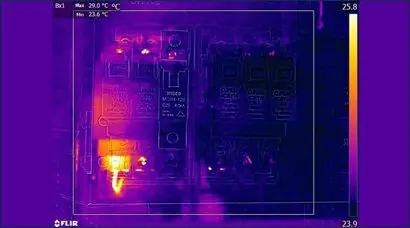

A thermographic scan utilises an infrared camera to document the temperature distribution on the surface of a piece of equipment. It is commonly employed for examining electrical distribution boards, also known as switchboards.

Detecting Hot Spots

Thermographic scanning can identify "hot spots," which indicate areas of elevated temperature relative to:

Hot spots represent potential faults, either presently or in the future. Skilled professionals can analyse and prioritise these faults for investigation in compliance with industry standards.

Unlock the Benefits of Thermal Imaging for Your Business

Discover how our cutting-edge Thermal Imaging Scanners and Basic Electrical Works can significantly improve your business operations. With Maratustech's advanced technology, you can take advantage of the following benefits:

What Are the Benefits of Thermal Image Scanning?

The utilisation of thermal imaging for early detection of equipment failure provides direct advantages, including:

Cost Savings

Thermal scanning is the most cost-effective preventative method available. By taking necessary precautions, thermal scanning helps minimise downtime and safeguards your business.

Non-Destructive Testing

It allows for the identification of heat-related external anomalies without the need to disconnect or damage any equipment. Additionally, internal equipment failure can often be detected through this method.

Minimisation of Workplace Hazards

Thermal image scanning reduces the risk of fire and other workplace hazards.

Early Detection of Potential Faults

By conducting thermal image scanning, potential faults can be identified at an early stage, enabling timely intervention and preventive measures.

How Often Do Switchboards & Other Electrical Equipment Need to Be Scanned?

Annually scans are vital in an effective preventative maintenance regime by capturing and documenting temperature changes over time. Additionally, ad hoc scans are beneficial prior to and following major system upgrades, particularly when new equipment substantially increases the electrical circuit load. These scans help ensure that equipment operates within normal parameters post-upgrade and verify the correct completion of the upgrade.

The Importance of Infrared Thermal Scanning for Early Detection

In the realm of electrical systems, the occurrence of a problem is often only recognised when a failure takes place. Such downtime can be both costly and devastating to a business. However, using infrared thermal scanning can identify issues before they escalate into system failures or fires.

Early detection is made possible through the observation that electrical components undergo a heating process before reaching a critical state. Maintenance personnel can use infrared thermal scanning to identify and address these escalating concerns before a component fails.

Infrared thermography is a valuable tool for inspecting electrical equipment due to its ability to identify excessive resistance within electrical apparatus. This resistance indicates various electrical faults, including:

The Importance of Including Thermal Scanning in Regular Planned Maintenance

Incorporating thermal scanning as part of your regular planned maintenance offers significant benefits by identifying issues that can be addressed during scheduled maintenance windows or periods of downtime. By proactively detecting and resolving these problems, your system can operate at its maximum efficiency, improving your business's reliability and cost-efficiency.

The Importance of Utilising Thermal Imaging for Early Equipment Failure Detection

Incorporating thermal imaging for early detection of equipment failure provides a range of advantages, including:

Important Note

Insurance companies highly recommend regular performance of this specific diagnostic survey. In fact, some insurance policies make it mandatory due to the recognised effectiveness of thermal imaging as a brilliant fire prevention method.

How Can Maratustech Help?

With over 30 years of experience as an Electrician and a passion for photography, I have found that thermographic scanning combines two major aspects of my life. Just as a professional photographer relies on the best tools to achieve the best outcome, the same applies to thermography. While inexpensive thermal cameras may capture thermal images, they lack the necessary definition and resolution, especially when inspecting switchboards for precise component identification. That's why, unlike other companies, we utilise top-of-the-line FLIR Cameras, such as the E96 model valued at around $25,000.00, instead of cheaper phone attachments priced at $800.00.

Thermographic Inspection Report

At Maratustech, we offer routine thermal scanning of electrical switchboards as part of our annual maintenance program. After conducting an initial thermographic survey, we provide a detailed thermographic inspection report that covers:

With our professional thermographic services, we prioritise providing comprehensive and detailed information to help address any issues with your electrical equipment.

Choose Maratustech for reliable thermographic services and basic electrical works. Our expertise, backed by top-quality cameras and years of experience, ensures accurate results for identifying potential issues in your electrical equipment.

Contact us today for professional solutions in the Sydney, Newcastle, and Central Coast regions.