RCD TESTING 30 Years of Electrical Expertise

A residual current device ( RCD ), or safety switch, protects you from the most frequent cause of electrocution - a shock from electricity passing through the body to the earth. It can also provide some protection against electrical fires.

RCDs are electrical safety devices designed to immediately switch off the electricity supply when electricity leaking to the earth is detected at harmful levels. They offer high levels of personal protection from electric shock.

Workplace injuries and fatalities can be prevented using properly installed and maintained residual current devices.

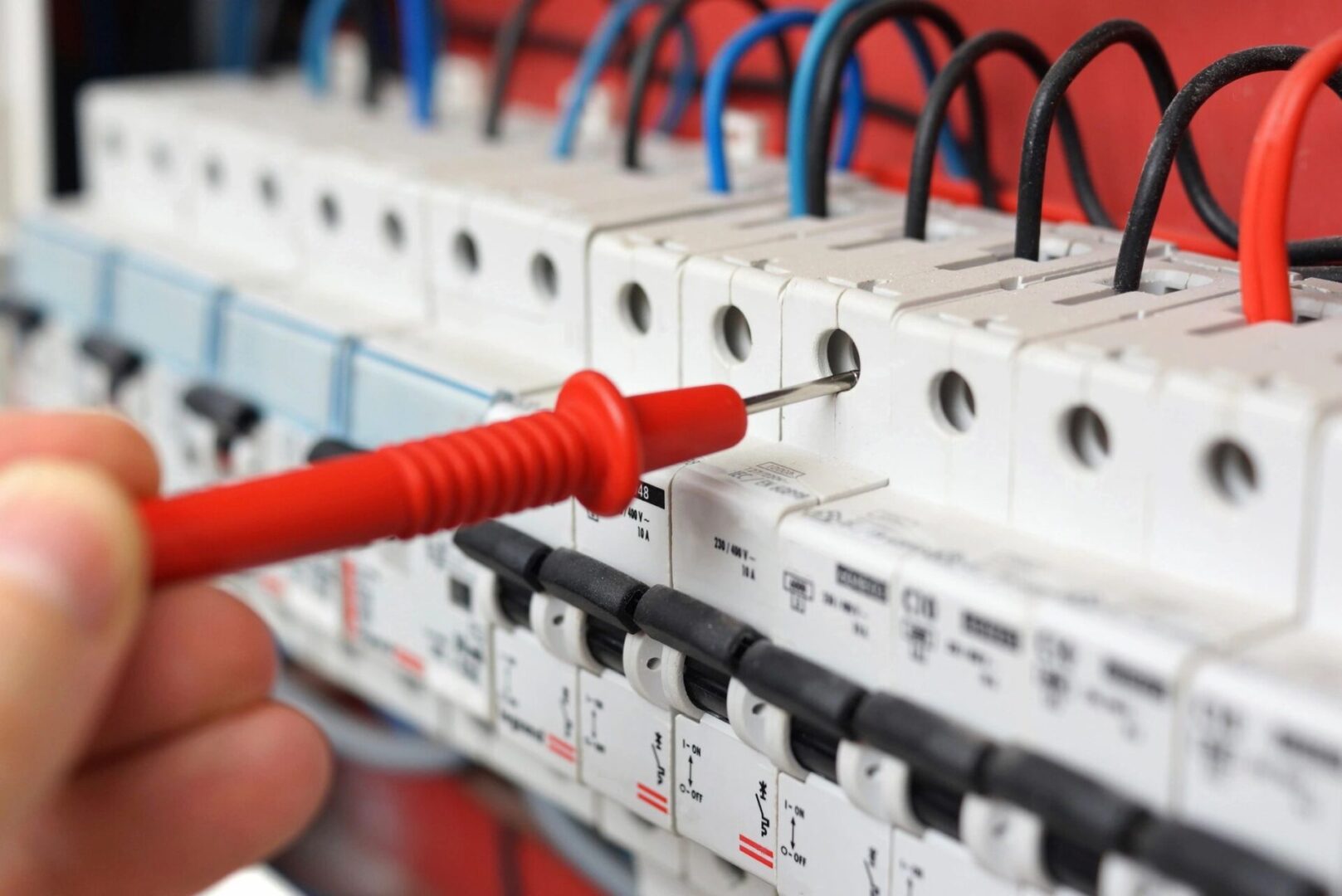

RCD Testing includes:

Upon completion, you will be issued with a Comprehensive Report recording all test results and actions taken.

When RCDs must be provided for use in workplaces

RCD requirements only apply in relation to workplaces where electrical equipment supplied with electricity through a socket outlet (plug-in electrical equipment) is used or may be used in certain higher-risk workplaces. These are workplaces with operating conditions where:

Common examples of electrical equipment requiring an RCD include:

Additional RCD requirements may be included in AS/NZS 3000:2007, local building and electrical safety laws.

WHY GET AN RCD TEST?

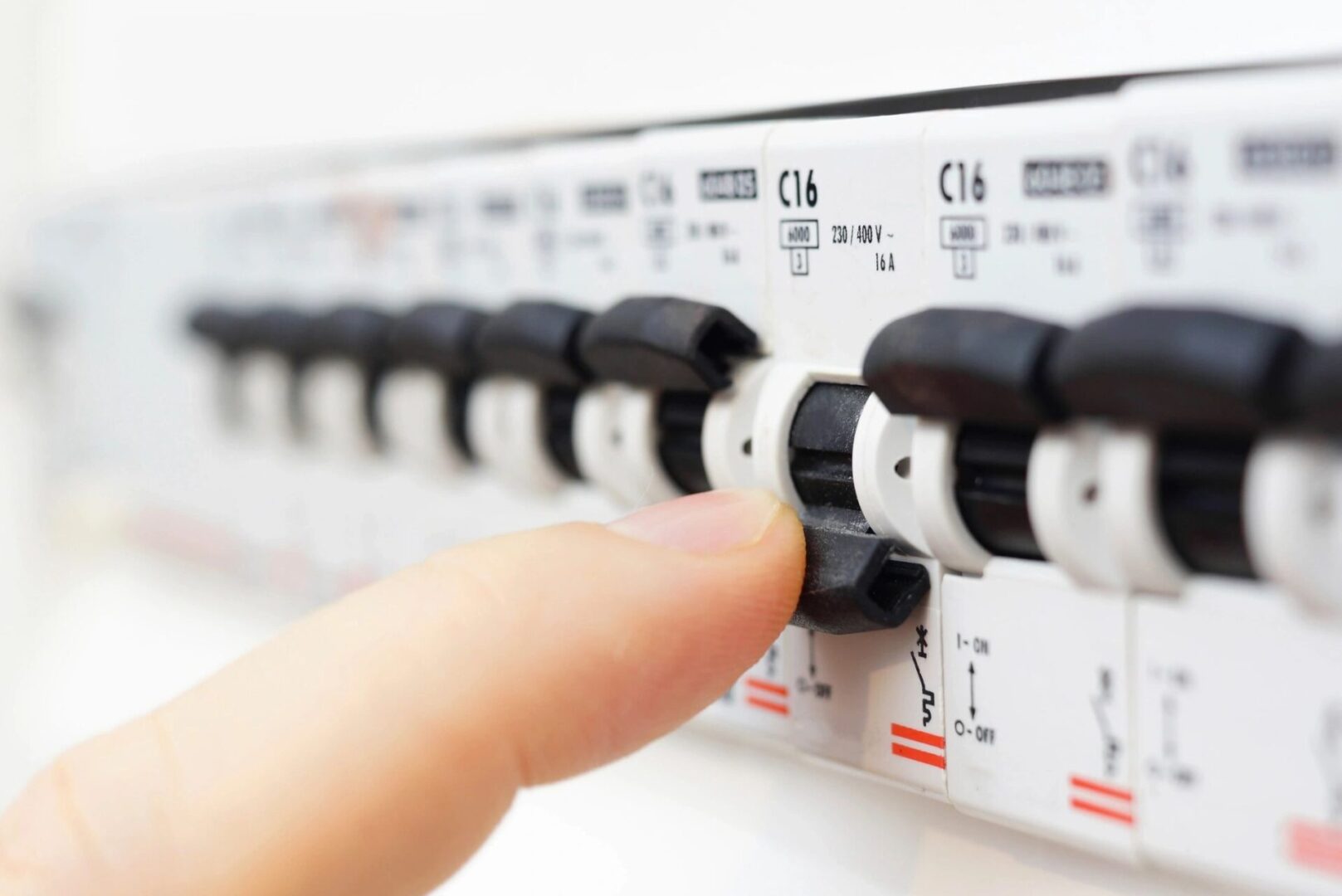

If you are a person with workplace management, you must ensure that RCDs used at work are tested regularly by a competent person to ensure they are working effectively.

A record of testing (other than push button testing) must be kept until the device is next tested or disposed of.

To fulfill your Australian Standard AS/NZS 3760 obligations, you must conduct 6 monthly RCD trip times and current tests performed on your premises.

Your RCDs must be compliant and tested per the Australian Standard AS/NZS 3760:2010.

Why use Maratustech for your RCD TESTING?

We have been involved in RCD Testing and upgrading for many years now. We use the latest testing equipment and can perform numerous RCD tests.

When we test your RCDs and switchboard, we will be able to identify any circuits currently NOT protected by an RCD and provide a quotation and advice on upgrading to the protection of an RCD.